Understanding how a stitch is made is essential to troubleshooting both small and large sewing machine problems?whether you?re a repair technician, seamstress, or apprentice.

Many people find it difficult to locate reliable information on how a sewing machine makes a stitch, or why understanding the process is crucial for effective repairs and smoother sewing performance.

In this guide, I?ll do my best to explain how a stitch is formed and why knowing this process is key to mastering your machine.

The Role of the Needle in Stitch Formation

Before you can fix or prevent thread problems, you need to understand the anatomy of a sewing machine needle and its critical role in creating a stitch.

Every needle has a distinct front and back?and this has nothing to do with the orientation of the sewing machine itself. No matter how the needle is inserted, the thread always goes in through the front and comes out the back of the needle.

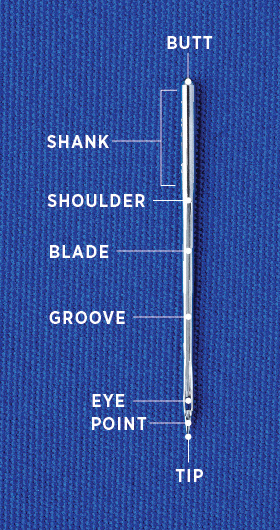

Let?s break down the parts of the needle and their functions:

- The Butt: The top of the needle, beveled for easy insertion into the needle bar. It rests

against the needle stop when properly installed.

against the needle stop when properly installed. - The Shank: Varies in size, length, and shape depending on the machine. Most domestic sewing needles have a flat side, while industrial or commercial needles are usually round. The shank secures the needle in the needle bar.

- The Shoulder: The transition between the shank and the blade (also called the shaft). It?s proportionate to the size of the needle.

- The Blade or Shaft: The main body of the needle that determines its size and length. It also houses the groove, which plays a vital role in guiding the thread.

- The Groove: The thread?s pathway, extending from the bottom of the shoulder to the top of the eye. The groove protects the thread, reduces friction, prevents fraying, and guides it smoothly into the eye.

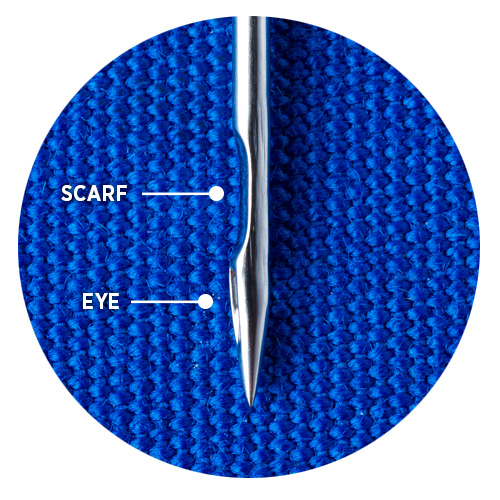

- The Eye: This is where the thread passes through the needle, from front to back?where the magic of stitch formation begins. The size and shape of the eye depend on the specific type and size of the needle.

- The Scarf: A small cutout on the back of the needle just above the eye. This space allows the hook to pass closely behind the needle without striking it, so it can catch the upper thread.

- The Point: The very tip of the needle, located below the scarf. Its design varies based on

the type of fabric being sewn. For example, a leather needle has a cutting tip that slices into the material, while a universal needle has a sharp point that pierces woven fabric.

the type of fabric being sewn. For example, a leather needle has a cutting tip that slices into the material, while a universal needle has a sharp point that pierces woven fabric.

Remember: the back of the needle should always face the hook point of your machine. Once the needle is inserted correctly, you?ll thread it front to back?regardless of the machine?s design.

If you have any questions about this section, feel free to drop them in the comments below!

How a Sewing Machine Stitch Is Made

Now that you understand the needle?s role, let?s explore how a sewing machine actually makes a stitch.

- The needle carries the top thread down through the fabric.

- Just as the needle begins to rise, the hook moves across the scarf of the needle and catches the loop of threadformed as the needle comes up.

- At this same moment, the take-up lever moves downward, creating slack in the thread so the hook can pull it smoothly around the bobbin case and bobbin.

- This action loops the upper thread completely around the lower (bobbin) thread, forming the lockstitch.

- As the hook moves past the halfway point around the bobbin case, the take-up lever rises again, pulling the thread back up and tightening the stitch.

- The tension assembly maintains proper tension on the upper thread to prevent it from being pulled off the spool prematurely.

- Then, the process begins again?creating the neat, balanced stitches that hold your fabric together.

Why Understanding Stitch Formation Matters

Knowing how a sewing machine stitch is formed helps you recognize and correct common sewing issues such as:

- Skipped stitches

- Thread bunching underneath the fabric

- Broken or frayed thread

- Uneven tension

- Needle strikes or timing issues

When you understand the mechanics of stitch formation, you gain the power to troubleshoot your own machine, extend its lifespan, and achieve cleaner, more professional results with every project.

Final Thoughts

Whether you?re repairing sewing machines, learning to sew, or simply curious about how your machine works, understanding how a stitch is made is one of the most valuable pieces of knowledge you can gain.

It?s the foundation of everything that happens under the needle?and once you understand it, you?ll never look at sewing the same way again.