The importance of a tool depends on the job it preforms. You probably hold your vehicle in high regard as it gets you from point a to point b. On the other hand you may not see a skate board very important even though it can also get you from point a to point b.

So how important are sewing machine needles to you? How much time and effort do you put into ensuring your needle is properly inserted and in good condition? Do you make sure you are using the correct needle for the project you are sewing?

As a repair technician, about half of the problems I see are needle-related or caused directly by the needle in the machine. Taking your sewing machine needle seriously will save you time, money, and frustration.

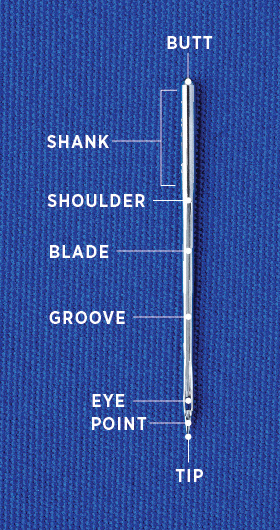

Anatomy of a Sewing Machine Needle (Parts and Functions)

The first step is to know and understand the different parts of the needle and their functions.

Butt

The top of the needle is the butt. It literally butts up against the needle stop in the needle bar.

Shank

The shank fits into the needle bar and holds the needle in place with the help of the needle bar screw. Most domestic machine needles have a flat side on the shank. This flat helps ensure the needle is inserted in the correct orientation for the machine.

Shoulder

The shoulder tapers the needle down to its marked size and connects the blade to the shank.

Blade

The blade makes up the main length of the needle.

Groove

The groove is built into the front of the blade. It provides a path for the thread to follow and protects it from friction and breakage as the thread moves back and forth through the fabric.

Eye

Eye

The eye is located at the end of the groove. It carries the thread through the needle from front to back?this is where the magic begins.

Point

The point is everything below the eye. It is engineered to work best with the specific fabrics the needle is designed for.

Tip

The tip starts the needle?s path into the fabric and cuts, punches, or pushes an opening based on the material it is intended to sew.

??????????????????????????????????????????????

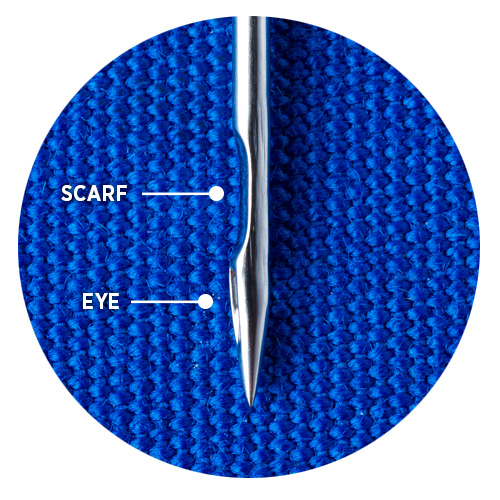

Scarf

On the back side of the needle, just above the eye, is the scarf. Its purpose is to create space for the hook to pass close to the needle and grab the upper thread. This helps prevent skipped stitches.

Inspect Every Sewing Machine Needle Before Use

Inspect every needle before putting it into your machine. Make sure:

- The needle is not bent or defective

- The eye is directly below the groove

- The scarf is on the opposite side of the groove and directly above the eye

- If the needle has a flat, it is on the same side as the scarf (the back of the needle)

To reduce the chances of defective needles, use well-known brands such as Schmetz, Organ, Singer, and Groz-Beckert. Off-brand or lesser-known needles tend to have a higher defect rate. If you consistently find defects with a particular brand, switch brands to save yourself frustration and potential machine problems.

Understanding Sewing Machine Needle Packaging (Needle Systems and Sizes)

Learning how to read needle packaging will help you find the right needles quickly and with less hassle. There are two main things to look for when buying needles: needle system and needle size.

Needle Systems

Unfortunately, there is no single industry standard for identifying needle systems.  Many manufacturers use their own identification methods, so one package may list several system numbers that all refer to the same needle.

Many manufacturers use their own identification methods, so one package may list several system numbers that all refer to the same needle.

For example:

130/705 H-ET

- 130/705: Needle system with a flat shank

- H: Haushaltsnadel (household/domestic)

- E: Embroidery

- T: Titanium coating

- 75/11: Needle size (0.75 mm diameter / Singer size 11).

???????????????????????????????????????Another package may list HAX1, 130/705 H, and 15◊1. These all describe the same household needle system with a flat shank. A size 80/12 indicates a 0.80 mm diameter needle or size 12 using Singer sizing.

Commercial Needle Systems

Commercial Needle Systems

Domestic (household) needles are very different from commercial needles. Commercial machines use a wide range of needle systems, often with many identification numbers referring to the same needle style.

For example, a single commercial needle may be labeled as: DB◊1, 1738, 16◊257, 17◊1, 16◊231, 287WH, DB◊257

These numbers describe shank size, needle length, and point type. The DB◊1 system is unusual because sizes up to 110/18 use a smaller shank for lightweight to medium fabrics, while larger sizes use a thicker shank for heavyweight fabrics. These needles are not interchangeable and may fit different machines despite having the same length.

??????????????????????????????????????

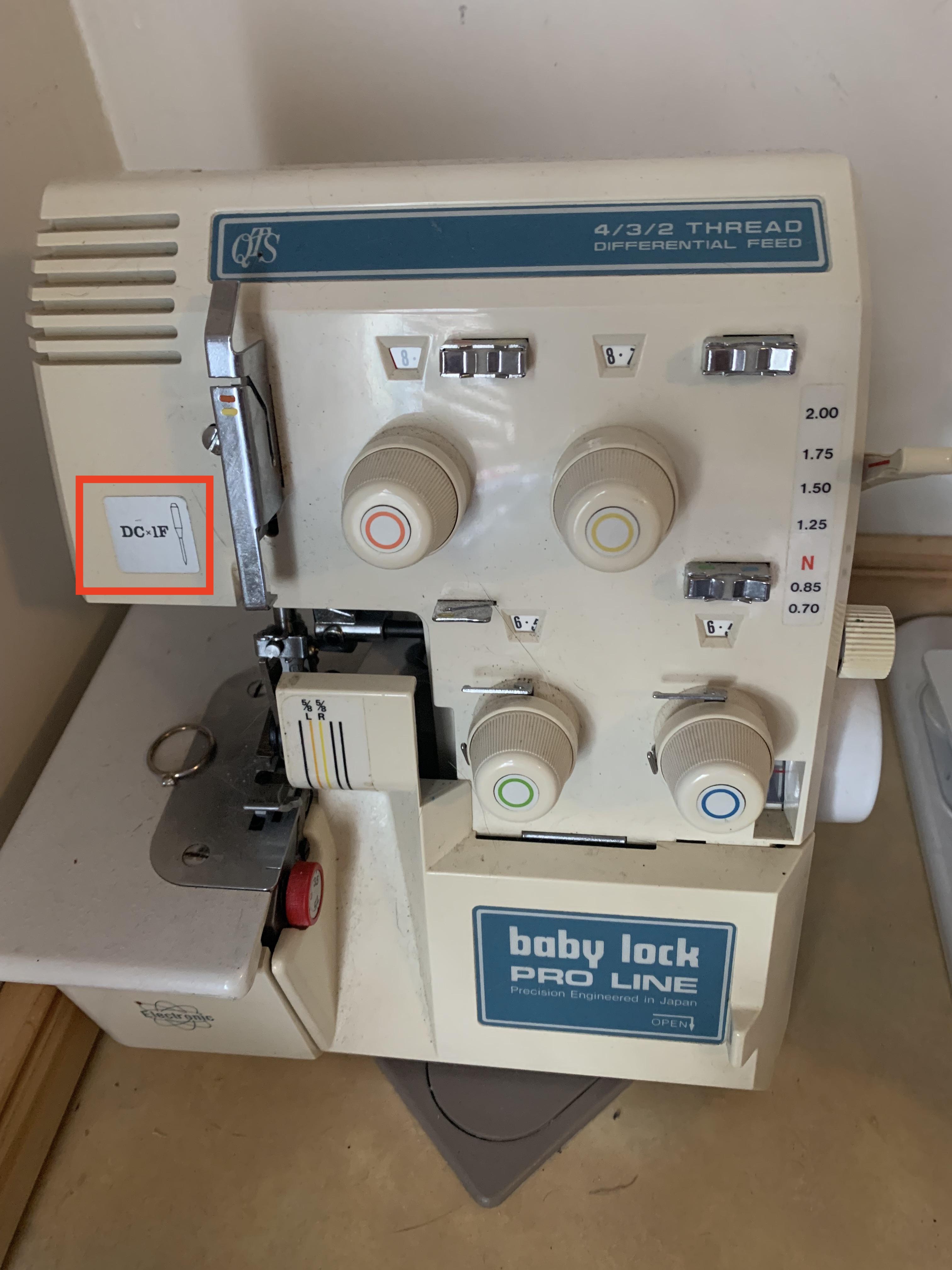

Most domestic sewing machines use the 130/705 H needle system. However, there are exceptions, such as certain older Baby Lock sergers that use DC◊1 or DC◊1F (a shorter needle with a smaller shank; the ?F? indicates a flat).

???????????????????????????????????????????????????????????????????????????????????????????????????????????

Many machines list the needle system directly on the machine. If not, refer to the owner?s manual?usually at the beginning of the needle section. Using the wrong needle system, even if it physically fits, often causes symptoms that look like timing problems.

Many machines list the needle system directly on the machine. If not, refer to the owner?s manual?usually at the beginning of the needle section. Using the wrong needle system, even if it physically fits, often causes symptoms that look like timing problems.

You can then google the system and find where you would like to buy the needles at.

Common Sewing Machine Problems Caused by Needles

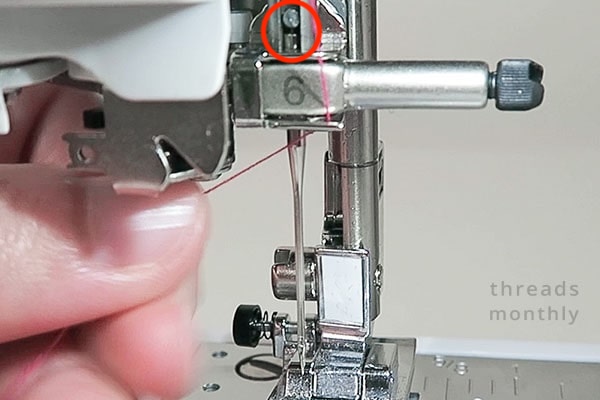

Improper Needle Insertion

One of the most common problems I see is improperly inserted needles. Every needle bar has a needle stop. In many machines, you can see the needle rise until it hits the stop. If the needle is not fully seated, it will sit too low and can cause skipped stitches or strike the hook, damaging or breaking the needle.

Some needle bars include a small inspection hole on the front, side, or back to help confirm proper insertion.

Incorrect Needle Size

Using a needle that is too small for the fabric or project thickness is another common issue. Many sewists consider fabric type but forget to account for fabric thickness or the number of layers.

A 75/11 needle works well for two layers of thin cotton with an occasional third layer at seams. If your project frequently has three layers or seams with four to six layers, an 80/12 or 90/14 is a better choice. Larger needles reduce breakage and improve stitch quality.

If a needle is too large, you?ll see visible holes in the finished seam. If it?s too small, the needle may deflect, hit the needle plate, or break while trying to penetrate dense layers.

???????????????????????????????

I personally recommend that most sewists use 80/12 as their smallest needle, except for very fine fabrics such as satin, chiffon, lace, or similar materials.

Slow down when sewing over seams. Thick transitions create angles that can push the needle off course and cause deflection.

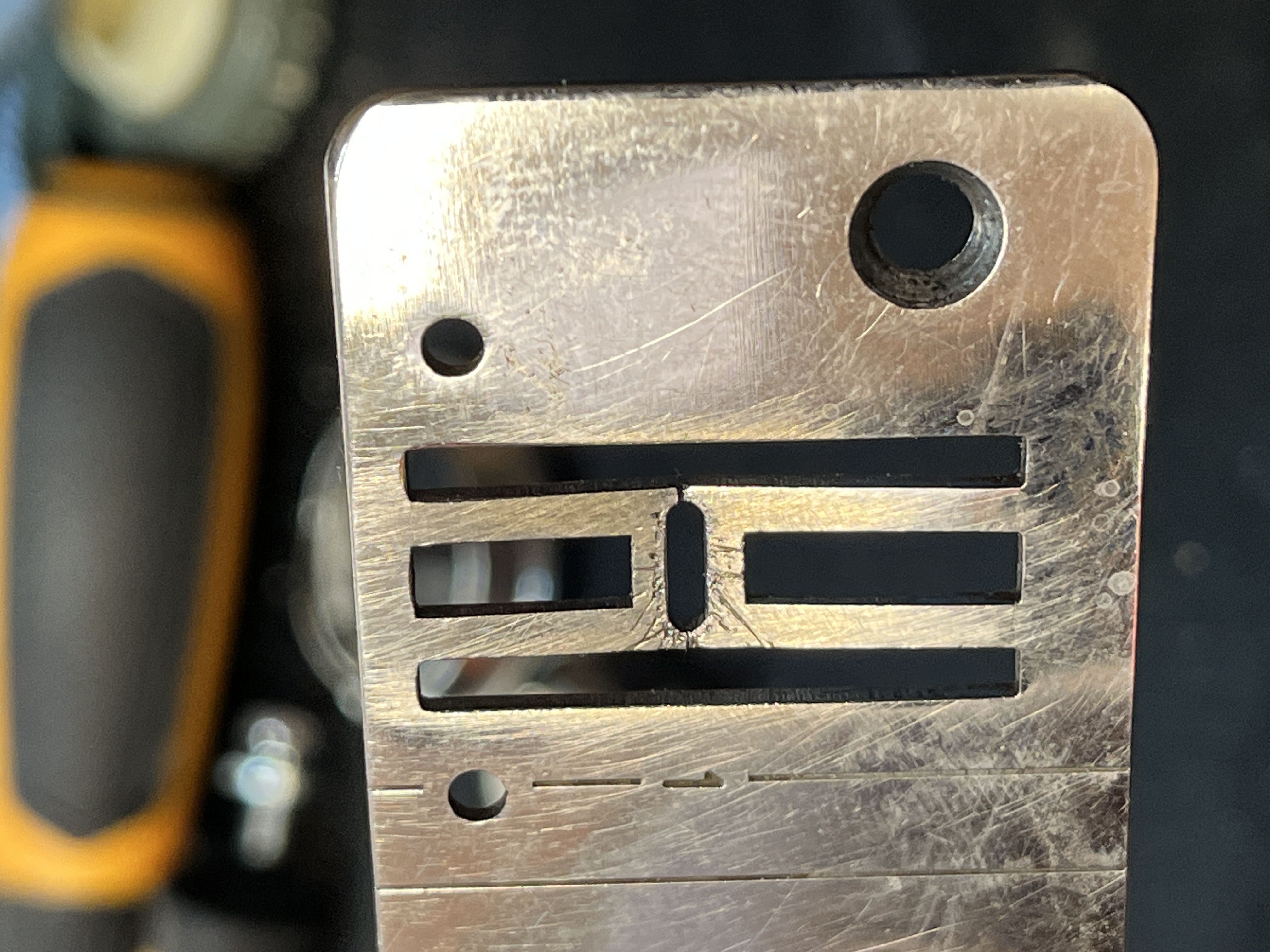

Here is an example of a needle plate that has been hit by the needle.

???????????????????????????????????????????????????????

?????????????????????????????????????????????????????????????????????You can see the extensive damage. It is bent in, broken on both sides of the needle hole, with divets and deep scratches from many needle hits.

This plate will cause thread looping, tearing and breaking.

???????????????????????

This can damage your project, cause frustration and a lot of time. All stemming from improper needle size and use.

When to Change a Sewing Machine Needle

Most needle manufacturers recommend changing needles every eight hours of sewing. Over time, needles become dull, making fabric penetration more difficult and increasing the risk of deflection.

Signs that a needle is dull or damaged include:

- Shredding or broken thread

- Skipped stitches

- Puckered or damaged fabric

- Uneven or wavy seams

- Popping, clicking, or clunking sounds

Always keep a variety of needles on hand for different machines and projects. You never know when you?ll need to replace one due to breakage, deflection, or accidentally hitting a pin.

If a needle strikes metal or plastic?such as the needle plate, hook, presser foot, or a pin?it is damaged and should be replaced immediately. A damaged or dull needle can ruin your project, cause looping or skipped stitches, and even damage your machine components such as the needle plate, hook, or bobbin case.

????????????????????

A damaged needle is never worth the risk?replace it right away.

Frequently Asked Questions About Sewing Machine Needles

How often should I change my sewing machine needle?

Most manufacturers recommend changing your needle every 6?8 hours of sewing time or at the start of every new project. If you hit a pin, presser foot, or needle plate, replace the needle immediately?even if it doesn?t look damaged.

Can the wrong needle cause skipped stitches?

Yes. Skipped stitches are very often caused by incorrect needle size, type, orientation, or a damaged needle. Before assuming timing is off, always check and replace the needle first.

What needle size should I use for most projects?

For general sewing, an 80/12 needle works well for most woven fabrics. Thicker projects or multiple layers may require a 90/14, while very fine fabrics may need a 70/10 or 75/11.

Why does my needle keep hitting the needle plate?

This is usually caused by an improperly inserted needle, needle deflection from thick seams, sewing too fast over bulky areas, or using a needle that is too small for the project.

Are expensive sewing machine needles worth it?

High-quality needles from trusted brands are more consistent, last longer, and reduce the risk of defects. They often save money in the long run by preventing machine damage and ruined projects.

Checklist

Here is a free needle check list you can print and put near your machine to double check when you are having problems

Download the Free Sewing Machine Needle Troubleshooting Checklist (PDF)

When Needle Problems Mean It?s Time for Professional Repair

If you?ve replaced the needle, confirmed the correct size and system, and still experience skipped stitches, thread breaks, needle strikes, or unusual noises, your machine may need professional service.

As a professional sewing machine repair technician, I see needle-related issues every day?many of which could have been prevented, and others that require precise adjustment and inspection.

If you?re located in Odessa, Texas or anywhere in the Permian Basin, and your machine isn?t sewing correctly, professional service can save you hours of frustration and prevent further damage.

Schedule a sewing machine inspection or repair today to keep your machine running smoothly and protect your investment.

? Visit the contact and booking page: https://odessasewingmachine.com/contact